pm01@hvhipottester.com

pm01@hvhipottester.com  pm02@hvhipottester.com

pm02@hvhipottester.com  8618986157274

8618986157274  +86 18986157274

+86 18986157274  live:1379417129

live:1379417129 1379417129

1379417129

This test is mainly to conduct a modal test of the turbine stator of the steam turbine unit. In order to prevent the generator from short-circuiting at the stator end due to insulation wear, rope breakage.......

HVPZ Dynamic Characteristics Test Of Steam Turbine Generator Stator End

This test is mainly to conduct a modal test of the turbine stator of the steam turbine unit. In order to prevent the generator from short-circuiting at the stator end due to insulation wear, rope breakage, and insulation water pipe leakage caused by unit vibration, timely discover and eliminate potential accidents, and ensure the safe operation of the unit, the end winding natural frequency of large generators should be tested to verify the quality of stator end fixation, further determine the rationality of the end design, and accumulate data for future tests.

This test plan is formulated based on the relevant provisions of the following national standards:

"Dynamic Characteristics and Vibration Measurement Method and Evaluation of Stator Winding Ends of Hidden Pole Synchronous Generators" (GB/T 20140-2016)

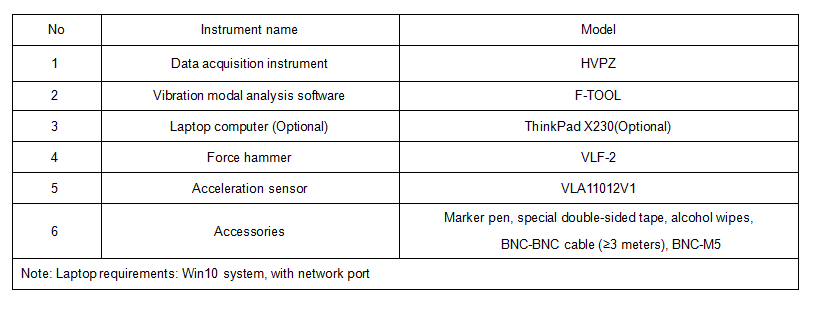

The hardware and software required for this test are listed in Table 3.1.

Table 3.1 Software and hardware required for the test

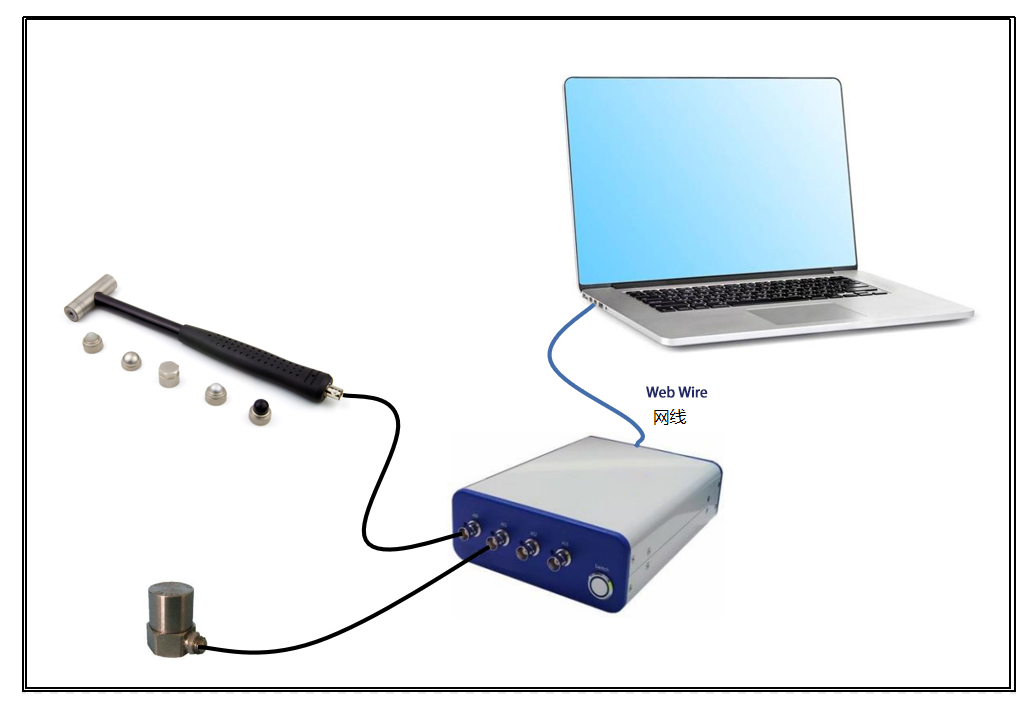

Instrument connection

The hammer and sensor are both IEPE type, directly connected to the acquisition instrument to form a steam turbine stator modal test system, and its connection diagram is shown in Figure 3.1.

Figure 3.1 Test system connection diagram

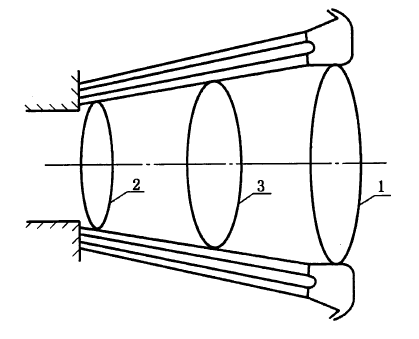

The test object is the turbine stator. The overall modal test of the stator winding end adopts the one-point response multi-point excitation method. A hammer is used to hit a certain point on the stator winding end to provide a transient impact force to the winding end. The data collector picks up the radial vibration response of the measurement point on the end winding, and then performs comprehensive analysis and processing on the data to obtain the overall modal frequency and vibration shape of the stator winding end.

The measurement points are arranged at the same inner diameter of the stator winding end, and one measurement point is arranged every other wire rod. The measurement point position should be selected at a relatively flat position, which is conducive to fixing the sensor and the knocking effect. If the number of stator slots is 42, there are 21 measurement points at the nose end of the winding end. According to the "Dynamic Characteristics and Vibration Measurement Method and Evaluation of the Stator Winding End of the Hidden Pole Synchronous Generator" (GB/T 20140-2016), the number of measurement points shall not be less than 18.

Marking

Use a marker to mark the selected measuring point. Start with 1 and mark one by one in a clockwise direction. Point 1 is usually selected at a relatively flat position on the bottom wire rod. Fix the sensor at point 1 during the test.

Fix the sensor

After selecting the measuring point, fix the sensor.

There is usually a small amount of oil on the surface of the wire rod. You can use an alcohol cotton ball or alcohol wipes to wipe the surface of the fixed sensor. Use a special double-sided tape to fix the sensor.

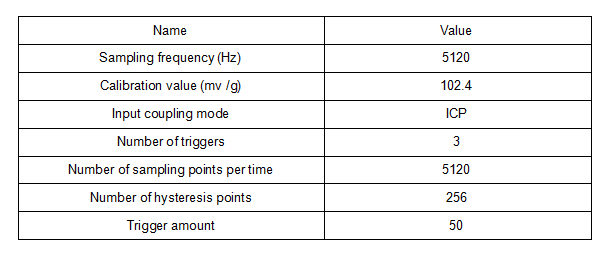

The main sampling parameter settings for the test are shown in Table 5.1.

Table 5.1 Main sampling parameter settings

1. When can I get the price?

We usually quote within 6 hours work time after we get your inquiry. If you are very urgent to get price, please call us or tell us in your email so that we will regard your inquiry priority.

2. What about the delivery time for production?

Honestly, it depends on the order quantity and the product. Usually our leading time is within 7 working days after order confirmation.

3. What is your payment terms?

We accept EXW, FOB, CFR, CIF, DDU, ect. You can choose the one which is the most convenient and cost effective for you.

4. How much will the Shipping cost and time be?

This will depend on size of your goods and method of shipping (by sea/ by air/by Express) and your designated seaport or airport. We will be grateful if you can spare us some minutes to evaluate the cost based on the information of product.

5. Could you please tell me the Warranty Period of your product?

Our warranty period is one year free and lifelong maintenance. If the product is damaged (if not man-made damage), in the first year,we will send free parts for replacement. Over warranty, maintenance is paid service.

6. Do you have Technical Backup to all customers from different countries?

To be sure,our technical support is always available and quick response.

We are manufacturer with much on-site testing experience, thus we know how to deal with your problems. Moreover, our engineers can go to your country to support if needed.