pm01@hvhipottester.com

pm01@hvhipottester.com  pm02@hvhipottester.com

pm02@hvhipottester.com  8618986157274

8618986157274  +86 18986157274

+86 18986157274  live:1379417129

live:1379417129 1379417129

1379417129 Tech: What is online and offline partial discharge test? Different application of instruments

Before explaining the difference between online and offline partial discharge testing, let's start with some information about partial discharge and its meaning

What is partial discharge?

Partial discharge is widely regarded as the main cause of long-term degradation and failure of high voltage equipment (MV, VH and EHV). Partial discharge is usually a small discharge that occurs between electrodes, but specifically at the location of insulation defects. Over time, these small discharges caused by uneven electrical pressure on the defect site will continue to damage the insulating layer until catastrophic failure occurs.

Online and offline partial discharge

Fortunately, there are some ways to detect these partial discharges before they fail. This is the place for online and offline testing.

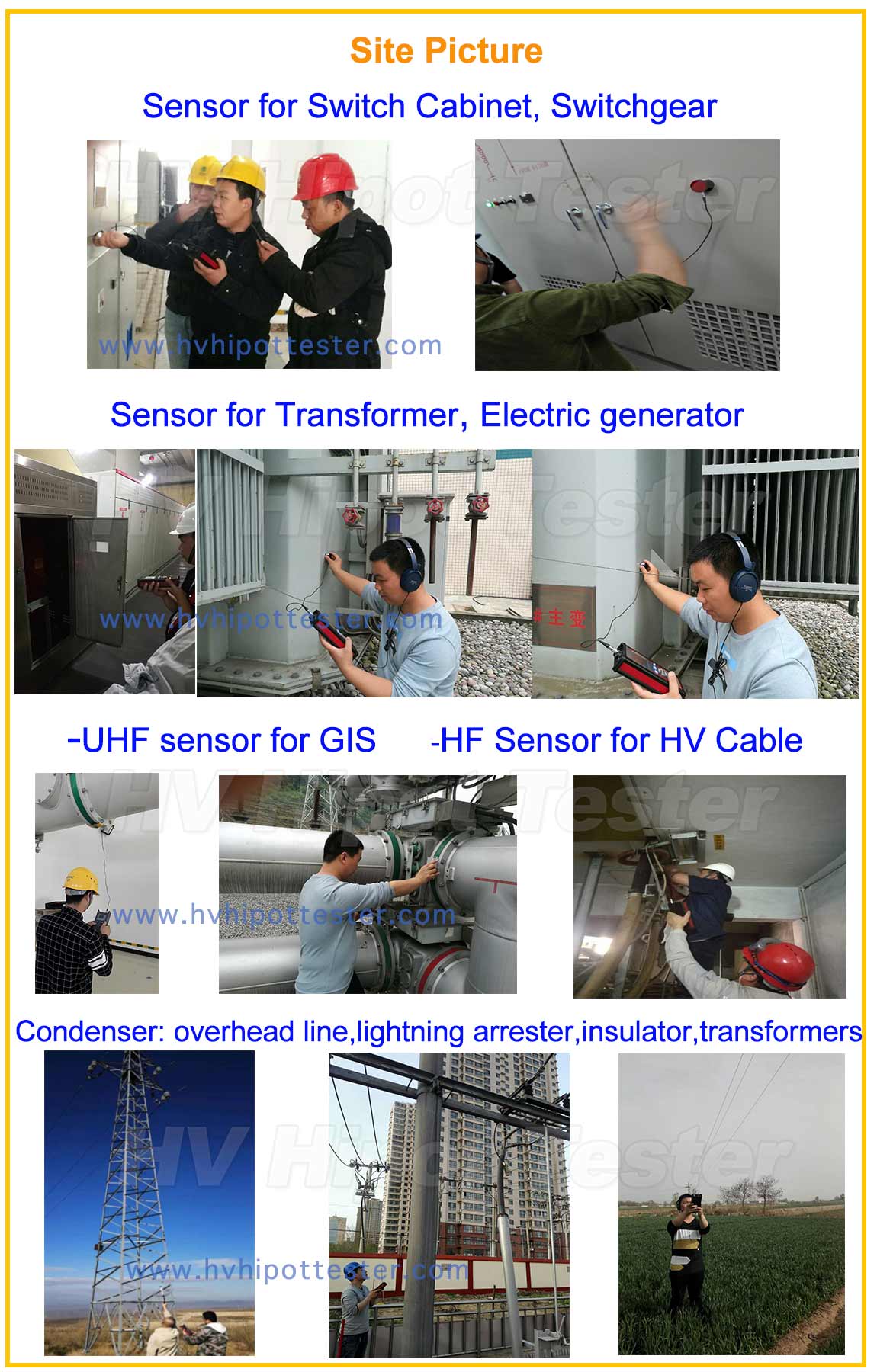

Depending on the type of defect and the asset to be tested, multiple technologies can be deployed for online and offline testing. Read on, we will explain the key features of each product.

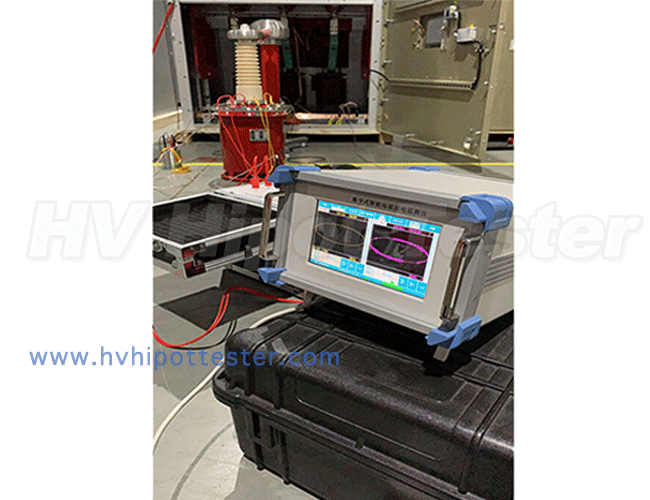

What is an online partial discharge test?

Perform an online test when the device is powered on at normal operating voltage. The test is carried out under real working conditions, typical temperature, voltage stress and vibration levels. This is a non-destructive test and will not use overvoltages that may adversely affect the equipment. Compared with offline testing that requires interruption of service and production, online partial discharge testing is relatively cheap. For critical facilities operating 24/7, this is the ideal solution for identifying insulation conditions.

Online and offline partial discharge

What is an offline partial discharge test?

Offline partial discharge testing involves switching the circuit to disconnect it, and then testing it with the (usually very low frequency) tester energized. When the voltage can be increased to a multiple of U0, it allows users to measure the response of the cable system to a specific stress level. Offline testing is useful for locating defects, because the noise level is much lower when offline compared to online. The challenge of offline testing is to make the device offline and stop using it. Offline testing is usually also used in acceptance testing of newly installed cables.

Is it necessary to conduct online and offline partial discharge tests at the same time?

Both online and offline methods form a part of a successful asset management plan. By combining different technologies, you can ensure the best equipment condition and reduce equipment failures and power outages.

On-line partial discharge can detect defects that occur under normal operating voltage, and defects that may not be detected offline. Offline testing can detect partial discharges that may not occur normally but will form in the future. Therefore, these two methods can provide a unique perspective, and usually the most mature test program will use both methods at the same time.