pm01@hvhipottester.com

pm01@hvhipottester.com  pm02@hvhipottester.com

pm02@hvhipottester.com  8618986157274

8618986157274  +86 18986157274

+86 18986157274  live:1379417129

live:1379417129 1379417129

1379417129

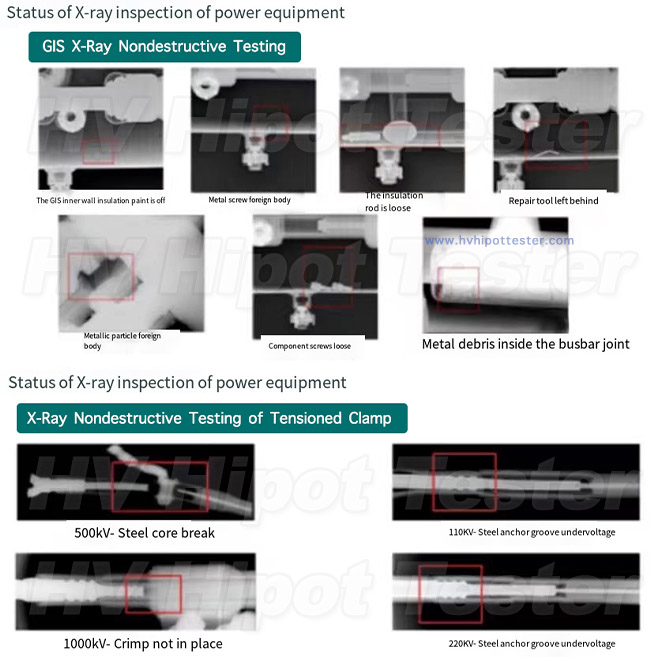

Portable X-ray machine-Detection instrument-X-ray equipment-X-ray digital imaging detection system,X-ray camera Portable X-ray machine, tension clamp non-destructive testing equipment, DR digital imaging detection system

HV-XRAY3543 Power Line Clamp Flaw Detector with Portable X-ray Machine & DR Camera Imaging System

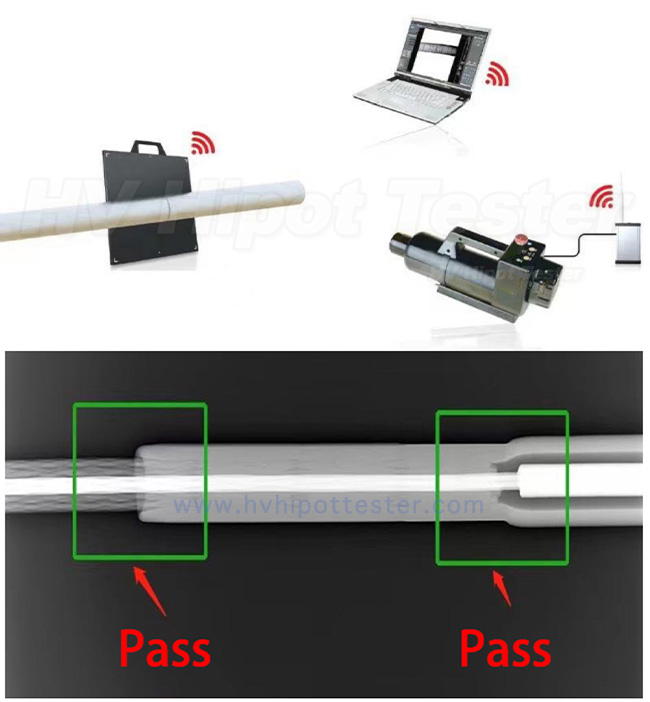

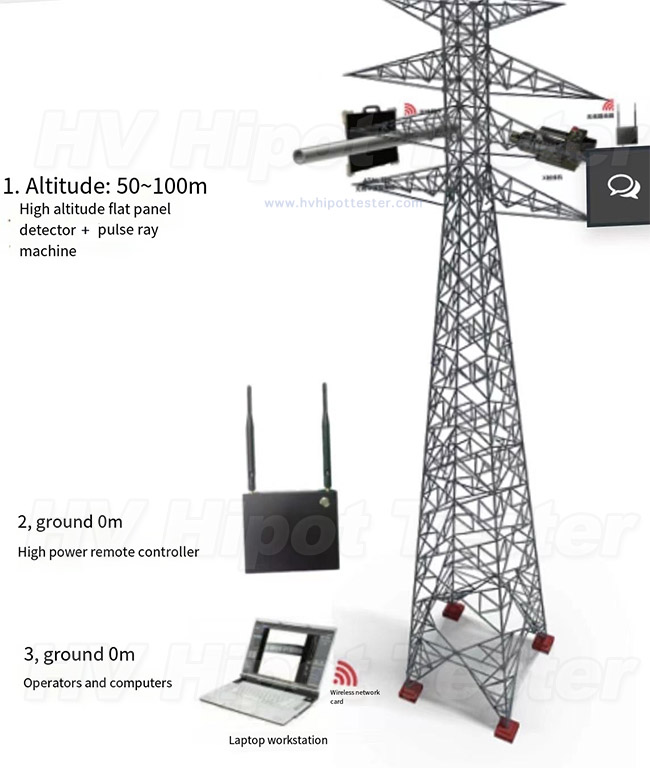

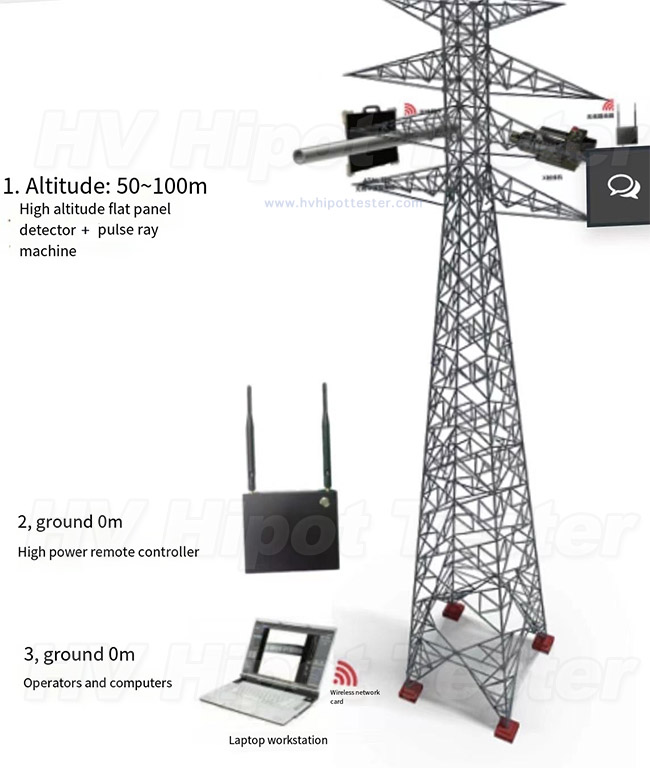

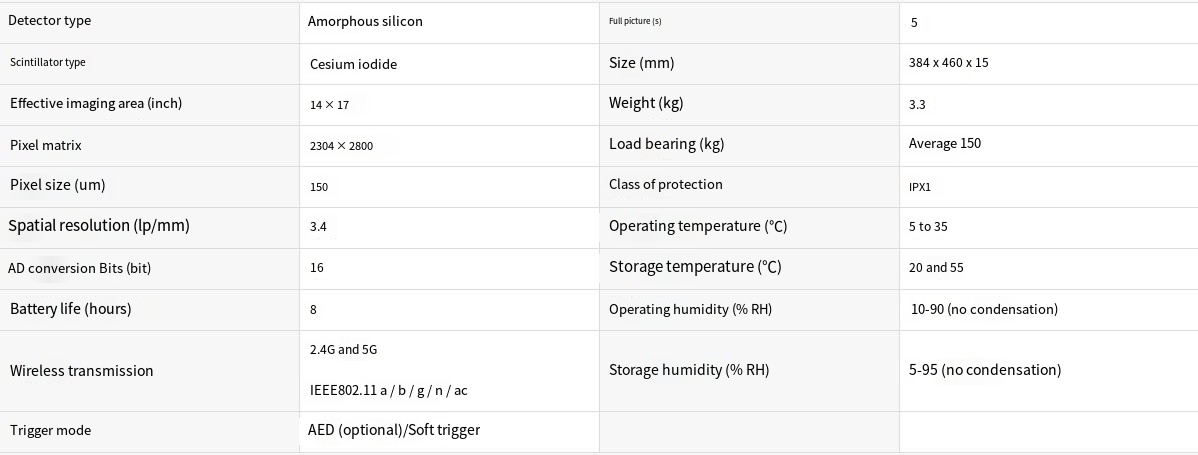

HV-XRAY3543 is a 14 × 17-inch wireless portable flat panel detector based on amorphous silicon sensor technology. It is shock-resistant and drop-proof.

The detector is designed for industrial ruggedness, making it highly radiation-resistant, adaptable to a wide range of environments, and highly reliable. Data and signal communications can be achieved through wired or wireless interfaces.

The SDK software development kit provided by our company supports the Windows operating system, allowing you to easily configure the detector parameters, calibrate, collect images, and observe images.

Due to its excellent image quality and reliability, the HV-XRAY3543 can be used in industrial inspections such as portable on-site inspections, power expansion clamp flaw detection, or suspicious object detection.

More information:

Project, News, Video,please kindly click the letters to view:

PRODUCT: UNDERGROUND CABLE/LINE/PIPELINE TESTING INSTRUMENT

VIDEO: CABLE/LINE/PIPELINE TESTING INSTRUMENT

NEWS: CABLE/LINE/PIPELINE TESTING INSTRUMENT

PROJECT:CABLE/LINE/PIPELINE TESTING INSTRUMENT

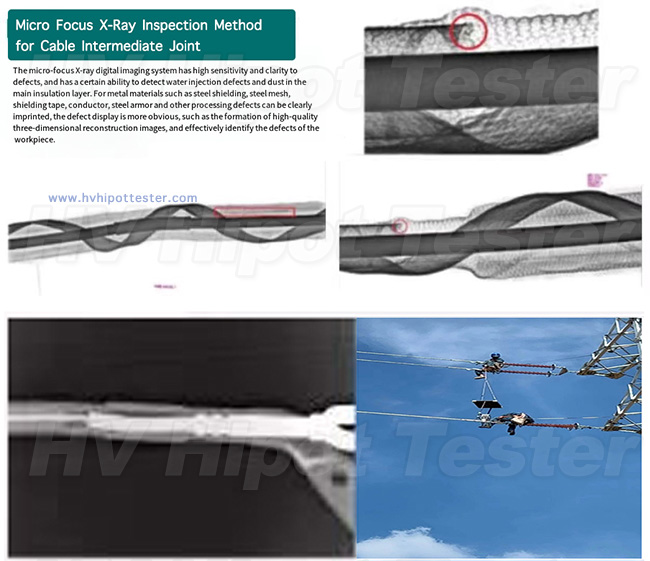

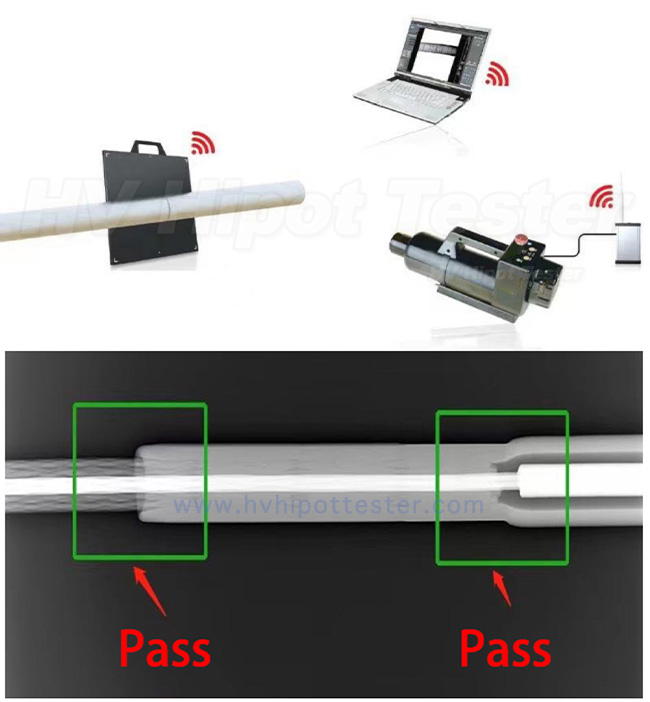

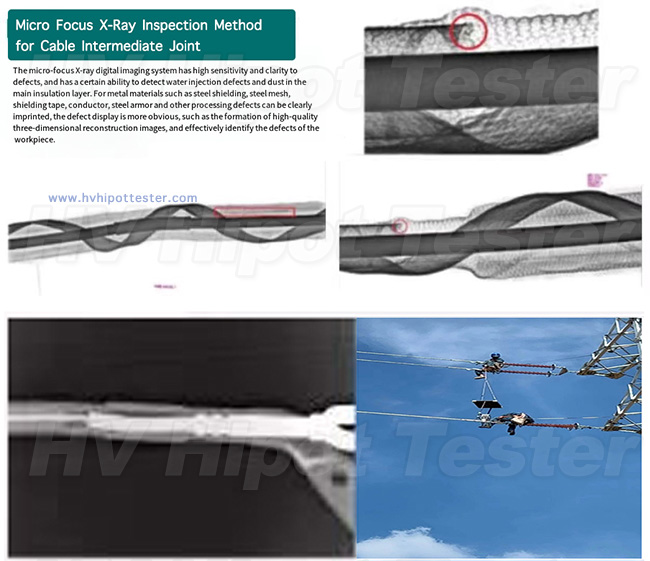

Micro Focus X-Ray Inspection Method for Cable Intermediate Joint

The micro-focus X-ray digital imaging system has high sensitivity and clarity to defects, and has a certain ability to detect water injection defects and dust in the main insulation layer. For metal materials such as steel shielding, steel mesh, shielding tape, conductor, steel armor and other processing defects can be clearly imprinted, the defect display is more obvious, such as the formation of high-quality three-dimensional reconstruction images, and effectively identify the defects of the workpiece.

Name | Parameter | Specification |

X-ray machine | Power Kv: 270 Ma: 0.25 Size: 36cmx15cmx10cm Power frequency: 50HZ-1HZ Weight: 5.5kg | Pulse exposure mode, high-efficiency exposure, strong penetration, easy to carry |

Flat-panel detector | Size: 35.0cmx43.0cm Pixel: 139um A/D conversion: 16Bit Pixel matrix: 3000x3000 Preview time: 3s Weight: 3.3kg | Cesium iodide amorphous silicon material, strong stability, high-speed image processing, excellent clarity, |

DR software | Powerful functions, efficient image reception, powerful processing modes such as splicing, optimization and cropping, easy to understand, and international standard DICOM30 format and storage modes | |

Li-ion battery | Size: 13cmx7cmx3cm Weight: 0.5kg | Multiple interfaces: 12v, 24v. Power supply time: 12 hours |

Wireless router | Size: 8cmx8cmx8cm Weight: 0.3kg | Long signal distance: 300m |

Portable support stand | Carrying size: 542mmx466mmx750mm Use size: 46cmx75cmx46cm Weight: 5kg | Easy to carry, simple to operate, wear-resistant, pressure-resistant, high temperature and cold-resistant |

Laptop computer | CPU: 2.5G Memory: 4G Disk memory: 256G Display: 11'' inches | Large memory, strong system, fast signal reception, portable |

1. When can I get the price?

We usually quote within 6 hours work time after we get your inquiry. If you are very urgent to get price, please call us or tell us in your email so that we will regard your inquiry priority.

2. What about the delivery time for production?

Honestly, it depends on the order quantity and the product. Usually our leading time is within 7 working days after order confirmation.

3. What is your payment terms?

We accept EXW, FOB, CFR, CIF, DDU, ect. You can choose the one which is the most convenient and cost effective for you.

4. How much will the Shipping cost and time be?

This will depend on size of your goods and method of shipping (by sea/ by air/by Express) and your designated seaport or airport. We will be grateful if you can spare us some minutes to evaluate the cost based on the information of product.

5. Could you please tell me the Warranty Period of your product?

Our warranty period is one year free and lifelong maintenance. If the product is damaged (if not man-made damage), in the first year,we will send free parts for replacement. Over warranty, maintenance is paid service.

6. Do you have Technical Backup to all customers from different countries?

To be sure,our technical support is always available and quick response.

We are manufacturer with much on-site testing experience, thus we know how to deal with your problems. Moreover, our engineers can go to your country to support if needed.